Numeric Control Machine with movable head with Gantry traction

| 70100 | 100100 | 150100 | |

| X | 7000 | 10000 | 15000 |

| Y | 1000 | 1000 | 1000 |

| Z | 500 | 500 | 500 |

| Other measures availables on demand | |||

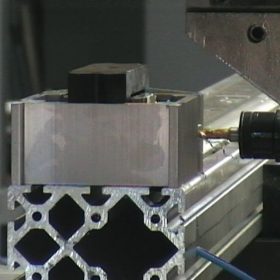

Constructive system:This serie incorporate a fixed bench and movable head system, adopting the format of head with traction in the axis “X” to both sides of the consoles, with two independents motors, called Gantry system, wich allows us to reach lengths in the “Y” axis up to 1000mm. and greater than 12000mm in the “X” axis, ensuring high precision and the absence of vibrations during the machining. The subjection is realized by pneumatic clamps, installed on consoles than can be posicioned automatically or manually. Machines with desplacements of up to 80 mt/min.

Pre-tightening safety cycle for securing the profile, for accident prevention. BENEFITS• 5 axis spindle SECTORSMATERIALES A MECANIZAR

Click here: Alufast/G to download the details file. |

||

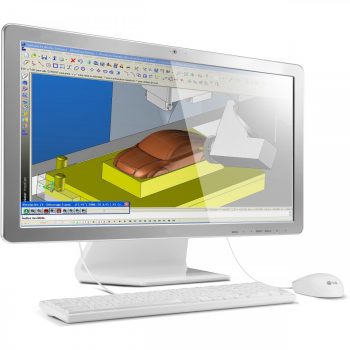

DETAILS

Spindle

Tool storage

CNC

Subjection

Lubrication

Sprayer

Tool measuring

SAMPLES

This is the selection we made for this machine